Thermocouple Links

The following links are thermocouple resources

Type R Thermocouple

(Platinum / Rhodium) 0°C to +1480°C / -32°F to +2700°F

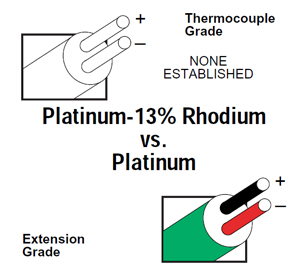

Postive Leg-Platinum/Rhodium{87% Platinum and 13% Rhodium}

Negative Leg-Platinum {100%}

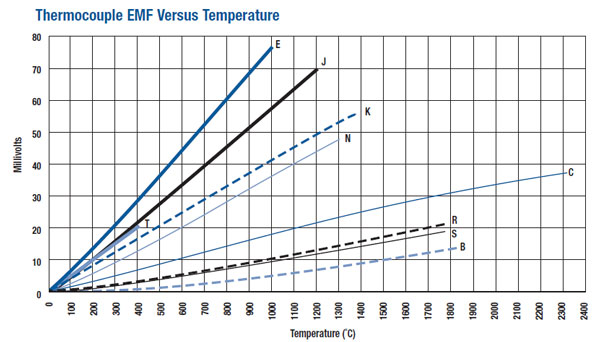

When protected by compacted mineral insulation and appropriate outer sheath, Type R Thermocouples are usable from 32°F to 2700°F. Type R thermocouples have a higher EMF output than type S. Type R Thermocouples are easily contaminated, and damaged in reducing atmospheres. Type R Thermocouples should be protected in similar fashion as Type S Thermocouples.

Type R Thermocouples are quite stable and capable of long operating life when used in clean, favorable conditions. When used above 1100° C ( 2000° F), these thermocouples must be protected from exposure to metallic and non-metallic vapors. Type R is not suitable for direct insertion into metallic protecting tubes. Long term high temperature exposure causes grain growth which can lead to mechanical failure and a negative calibration drift caused by Rhodium diffusion to pure platinum leg as well as from Rhodium volatilization. This type has the same uses as type S, but is not interchangeable with it.

Pros

Cons

Type R Thermocouple ( Platinum/Rhodium)

Type R thermocouple has superior mechanical properties to Type S and is recommended for continuous use in oxidizing and inert atmospheres around temperatures up to 1400°C and intermittently up to 1600°C. However, it should not be used in vacuum, reducing or metallic vapour atmospheres unless properly protected with clean high purity (>99.5%) Alumina insulators and protection tubes. Among precious metal thermocouples, Type R is most widely used.

Temperature Range:

•Thermocouple grade wire, −58° to 2,700°F (−50 to 1,480°C)

•Extension grade wire, −32° to 392°F (0 to 200°C)

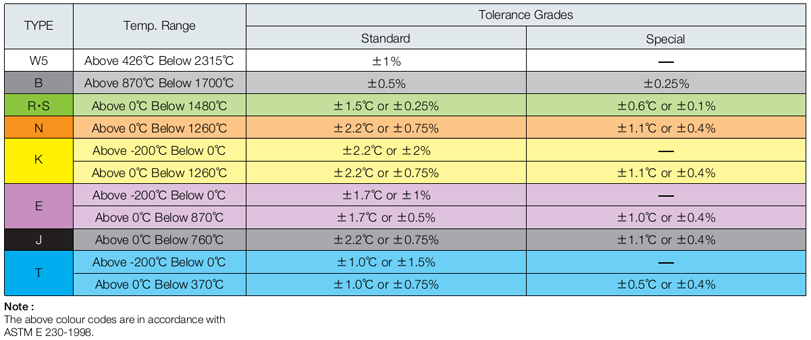

Accuracy (whichever is greater):

•Standard: ± 1.5C or ± .25%

•Special Limits of Error: ± 0.6C or 0.1%

Type R Thermoelectric Voltage

Type R Thermocouple Tolerances

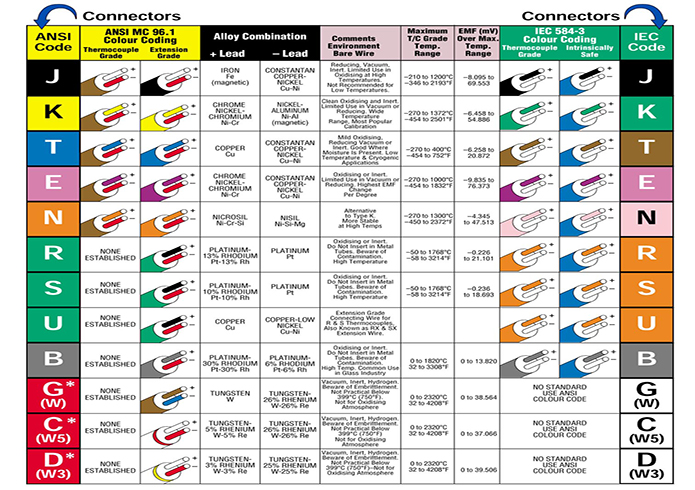

Type R Thermocouple Color Code

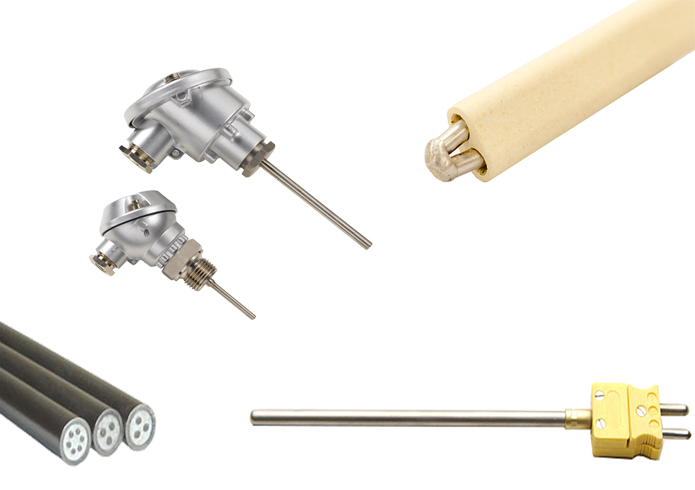

Type R Thermocouple Junctions

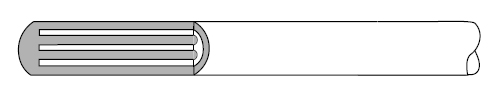

Grounded Thermocouple

This is the most common junction style. A thermocouple is grounded when both thermocouple wires and the sheath are all welded together to form one junction at the probe tip. Grounded thermocouples have a very good response time because the thermocouple is making direct contact with the sheath, allowing heat to transfer easily. A drawback of the grounded thermocouple is that the thermocouple is more susceptible to electrical interference. This is because the sheath often comes into contact with the surrounding area, providing a path for interference.

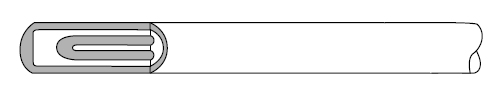

Ungrounded Thermocouple

A thermocouple is ungrounded when the thermocouple wires are welded together but they are insulated from the sheath. The wires are often separated by mineral insulation.

Exposed Thermocouples (or "bare wire thermocouples")

A thermocouple is exposed when the thermocouple wires are welded together and directly inserted into the process. The response time is very quick, but exposed thermocouple wires are more prone to corrosion and degradation. Unless your application requires exposed junctions, this style is not recommended.

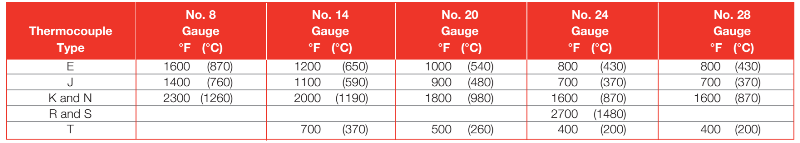

Type R Thermocouple Conductor Gauge

Thermocouple conductors come in a variety of sizes. Depending on your application, the gauge selected will affect the thermocouple's performance. The larger the gauge size, the more thermal mass the thermocouple will have with a corresponding decrease in response. The larger the gauge size the greater the stability and oper-ating life. Conversely, a smaller gauge size will have a quicker response, but may not deliver the stability or oper-ating life required.

Type R Thermocouple Sheath

316 Stainless Steel

Maximum temperature: 1650. Best corrosion resistance of the austenitic stainless steel grades. Widely used in the food and chemical industry. Subject to damaging carbide precipitation in 900°F to 1600°F (482°C to 870°C).

316L Stainless Steel

Maximum temperature: 1650°F (900°C). Same as 316 SST (04) except low carbon version allows for better welding and fabrication.

304 Stainless Steel

Maximum temperature: 1650°F (900°C). Most widely used low temperature sheath material. Extensively used in food, beverage, chemical and other industries where corrosion resistance is required.

Industry: Subject to damaging carbide precipitation in 900 to 1600°F (480 to 870°C) range. Lowest cost corrosion resistant sheath material available.

304L Stainless Steel

Maximum temperature: 1650°F (900?C). Low carbon version of 304 SST (02). Low carbon content allows this material to be welded and heated in the 900 to 1600°F (480 to 870°C) range without damage to corrosion resistance.

310 Stainless Steel

Maximum temperature: 2100?F (1150?C). Mechanical and corrosion resistance, similar to but better than 304 SS. Very good heat resistance.

This alloy contains 25% chromium, 20% nickel. Not as ductile as 304 SS.

321 Stainless Steel

Maximum temperature: 1600°F (870°C). Similar to 304 SS except titanium stabilized for intergranular corrosion.

This alloy is designed to overcome susceptibility to carbon precipitation in the 900 to 1600°F (480 to 870°C) range. Used in aerospace and chemicalapplications.

446 Stainless Steel

Maximum temperature: 2100°F (1150°C). Ferritic stainless steel which has good resistance to sulfurous atmospheres at high temperatures.

Good corrosion resistance to nitric acid, sulfuric acid and most alkalies. 27% chromium content gives this alloy the highest heat resistance of any ferritic stainless steel.

Inconel 600

Maximum temperature: 2150°F (1175°C). Most widely used thermocouple sheath material. Good high temperature strength, corrosion resistance, resistance to chloride-ion stress corrosion cracking and oxidation resistance to high temperatures.

Do not use in sulfur bearing environments. Good in nitriding environments.

Inconel 601

Maximum temperature: 2150°F (1175°C) continuous, 2300°F (1260°C) intermittent. Similar to Alloy 600 with the addition of aluminum for outstanding oxidation resistance. Designed for high temperature corrosion resistance.

This material is good in carburizing environments, and has good creep rupture strength. Do not use in vacuum furnaces! Susceptible to intergranular attack by prolonged heating in 1000 to 1400°F (540 to 760°C) temperature range.

Inconel 800

Maximum temperature: 2000°F (1095°C). Widely used as heater sheath material. Minimal use in thermocouples. Superior to Alloy 600 in sulfur, cyanide salts and fused neutral salts.

Susceptible to intergranular attack in some applications by exposure to the temperature range of 1000 to 1400°F (540 to 7607deg C).

How to measuere temperature with a Type R Thermocouple

A thermocouple circuit contains the two alloy junctions, wire sand connectors and a voltage measuring device. When the two junctions are experiencing different temperatures, measurable current flows through the circuit. The current is related to the temperature differential. Because the measurement is relative, one of the temperatures must be known in order to calculate an absolute temperature. In early thermocouples, one junction was kept at 0° C by immersing it in an ice water bath. Today, one of the junctions, the "cold junction," is electrically compensated to maintain a standard. The other junction, the "hot junction," is exposed to the environment to be measured.

Collecting data from a type R thermocouple

A Type R thermocouple can be connected to a voltmeter for simple data collection. In this case, the output is a voltage, and the reader has to convert the voltage level to temperature using a conversion formula. To record data, the thermocouple can be connected to a data logger or a data acquisition system to store collected data. In these cases, a conversion circuit or a software operation can be used to calculate the temperature using the voltage output.