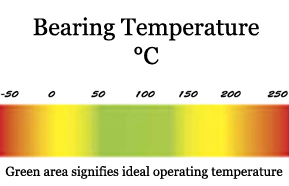

Bearing Temperature

The most reliable indicator of bearing condition is the temperature of the metal beneath the shoe.

Custom Bearing Sensor Designs

Thermometrics specializes in making custom sensors to our customers specification.

Bearing Sensor Stock

We stock an inventory of components to manufacture bearing sensors which we can provide same day shipping!

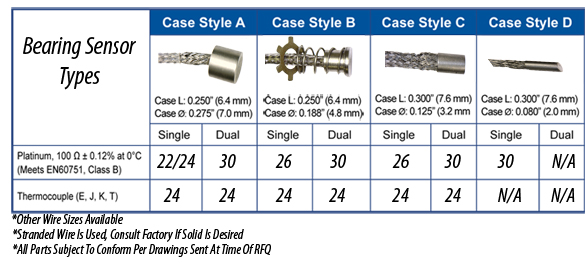

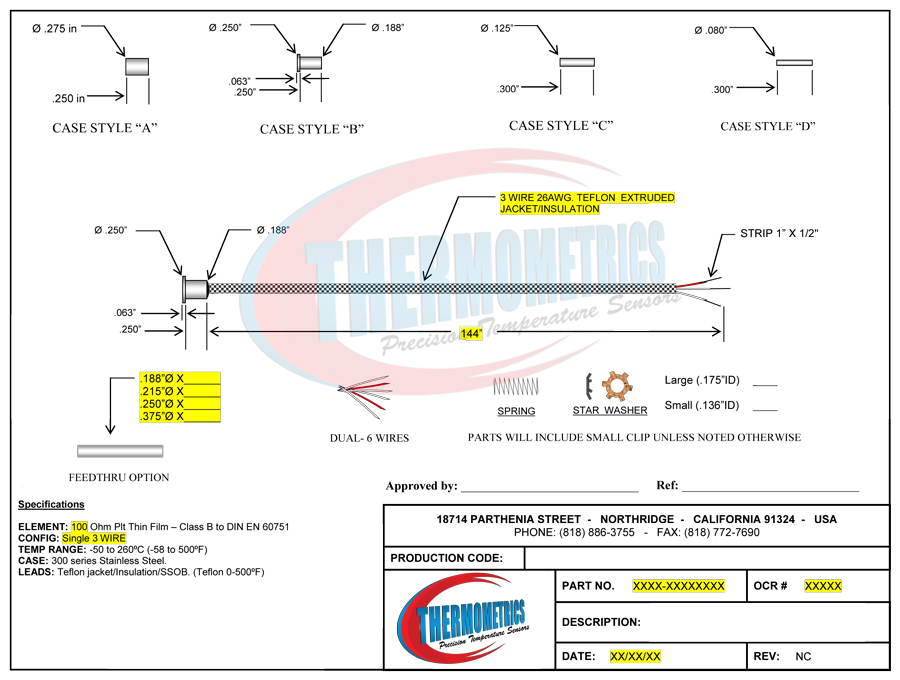

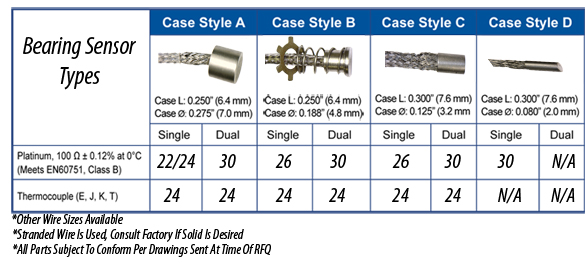

Bearing Sensor Case Style A

Case Style A-Ø=0.275"

L= 0.250"

Bearing Sensor Case Style B

Case Style B-Ø=0.188"

L= 0.250"

Bearing Sensor Case Style C

Case Style C-Ø=0.125"

L= 0.300"

Bearing Sensor Case Style D

Case Style D-Ø=0.080"

L= 0.300"

Bearing RTD 2-wire

2 wire rtd (±0.12% at 0°C)

Bearing RTD 3-wire

3 wire rtd(±0.12% at 0°C)

Bearing RTD 4-wire

4 wire rtd (±0.12% at 0°C)

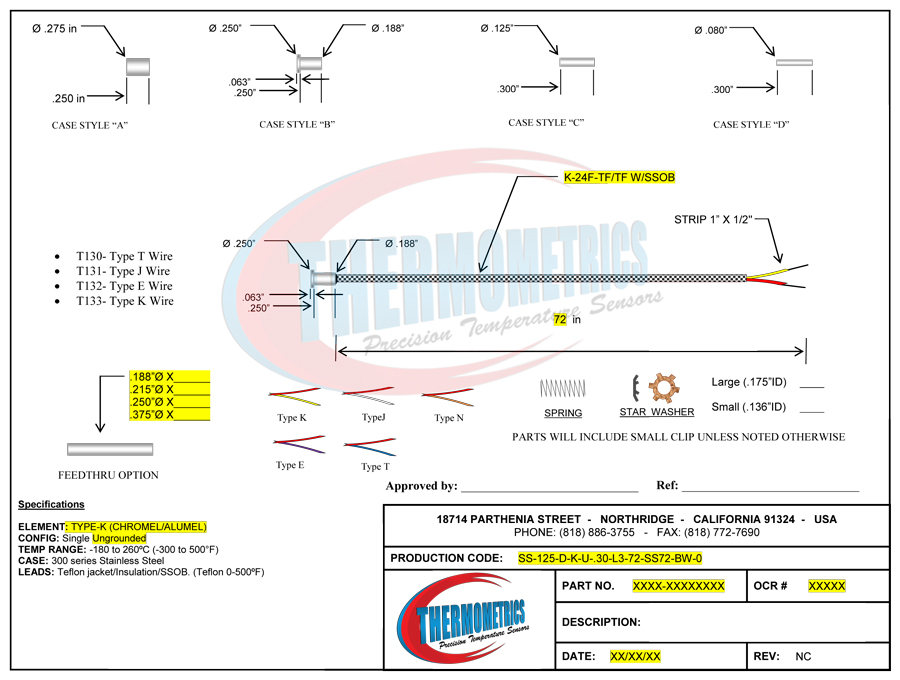

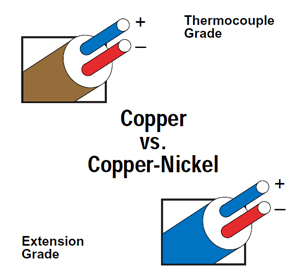

Bearing Thermocouple Wire

Type- E, J, K, TInsulated sensing junction

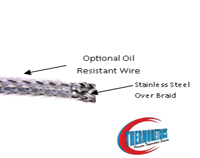

Bearing Sensor Wire Seal

Prevents oil from moving up the bearing sensor leads

Oil Resistant Wire

Bearing sensor optional oil resistant wire available

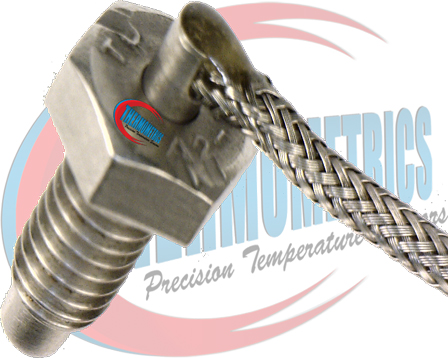

90° Bearing Sensor

This 90° design is inteded to relieve stress put on the wires by bending them.

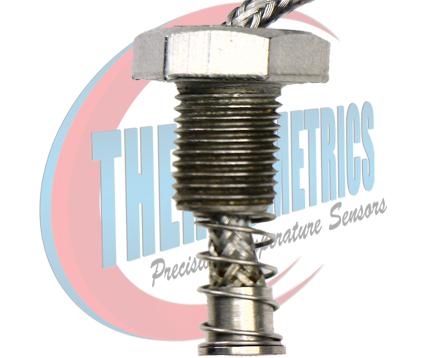

Screw In Free Spin Bearing Sensor

This design screws into a threaded hole and has 360° free spinning leads.

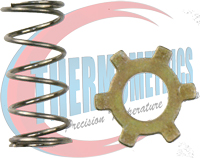

Bearing Sensor Spring and Washer

Optional Bearing Sensor spring and star washer.

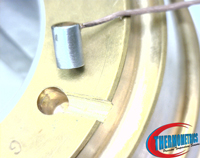

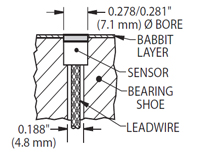

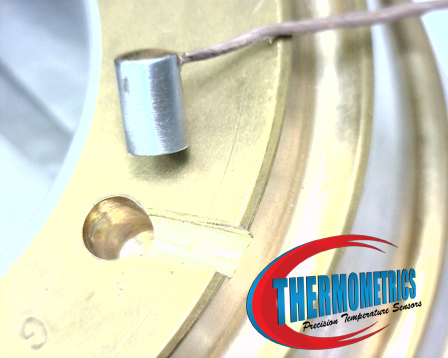

Bearing Sensor Installation

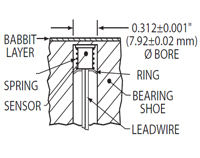

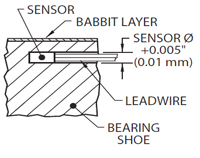

Install Case Style A sensor just below the babbitt layer, then puddle the babbitt metal over the sensor tip and smooth.

Bearing Sensor Installation

The Top Hat Spring Style retaining ring allows sping loading with the spring and retaining clip. Slide the spring and ring over the leads, insert the sensor tip into a milled hole, and push down on the retaining ring to compress the spring and secure the sensor.

Bearing Sensor Installation

Bond with epoxy inside bearing shoe. Locate near the babbit face for most accurate readings.Bearing RTD

Bearing RTDs are designed for areas where there are space limitations. They are small, compact and are often used to detect temperature increases in bearings, thrust bearing plates, shafts and motor windings. They are miniature low mass sensors which are fast responding. Bearing sensors are manufactured using thin film technology and by design are tip sensitive and vibration resistant. They can be spring loaded into a bearing housing or held in position with a high temperature epoxy resin.

Bearing RTD Applications

Bearing RTD Attributes

Bearing RTD Specifics

Bearing Thermocouple

BearingThermocouples are designed for areas where there are space limitations. They are small, compact and are often used to detect temperature increases in bearings, thrust bearing plates, shafts and motor windings. They are miniature low mass sensors which are fast responding. Bearing sensors are manufactured using thin film technology and by design are tip sensitive and vibration resistant. They can be spring loaded into a bearing housing or held in position with a high temperature epoxy resin.

Bearing Thermocouple Applications

Bearing Thermocouple Attributes

Bearing Thermocouple Specifics

Bearing Sensor Custom Designs

Thermometrics Corporation is dedicated to the continual improvement and development of our products. Our Engineering team's capabilities, knowledge, experience and on-site process evaluations provide you with support and the best possible temperature measurement results. If you are looking for prototypes that require special machined components, you can count on us to deliver them in a timely manner. Our in-house machine shop - complete with metal cutting, threading, shaping and finishing machinery, and stocked with a variety of raw material - compliments our Engineering, Design, and Production teams to manufacture sensors with special component parts.

Bearing Picture Gallery

Composed of a positive leg, which is approximately 90% nickel, 10 chromium and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon.

When protected by compacted mineral insulation and appropriate outer sheath, Type T is usable from 0 to 350°C, (32 to 662°F). Type T is very stable and is used in a wide variety of cryogenic and low temperature applications. For applications below 0°C, (32°F) special selection of alloys are usually required.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

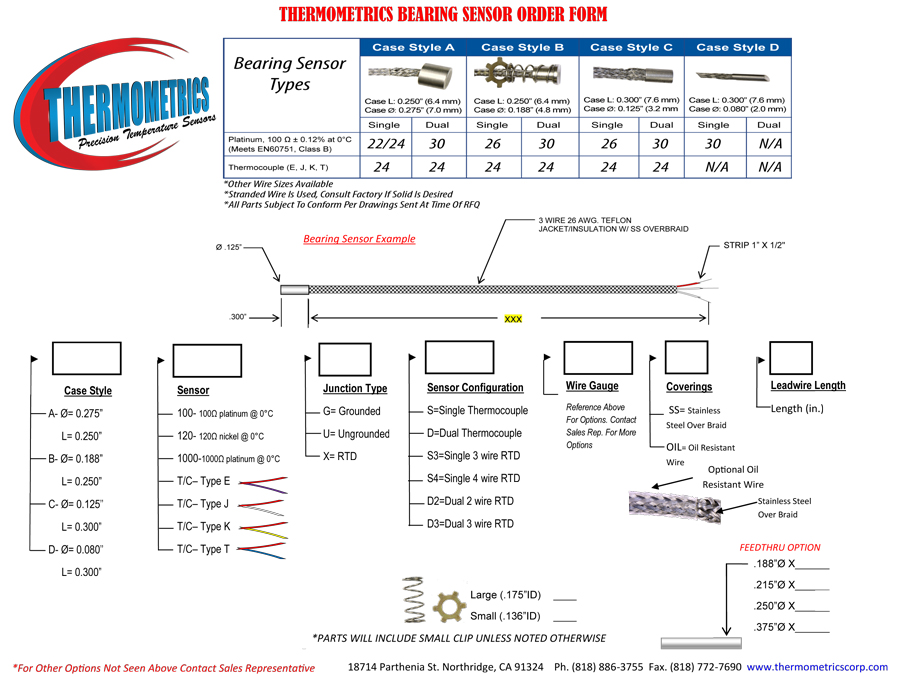

Bearing Sensor Order Form

Avoid costly plant shut downs with our express manufacturing service. We stock an inventory of components to manufacture babbit bearing sensors for high and moderate temperature service. Top hat, small profile bearing cap, and double oil seal configurations are routinely assembled with Nickel 120 ohm, Pt 100 ohm and thermocouples. With ove 45 years experience and a manufacturing facility on the West Coast, the days of waiting a week or two for delivery of critically needed embedded sensors are Over!

When protected by compacted mineral insulation and appropriate outer sheath, Type T is usable from 0 to 350°C, (32 to 662°F). Type T is very stable and is used in a wide variety of cryogenic and low temperature applications. For applications below 0°C, (32°F) special selection of alloys are usually required.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

- O's hit Bautista twice, Showalter tossed

- Phils clinch playoff spot despite loss

- Reds trim magic number to 1, rout Padres

- Cain flirts with no-hitter, Giants win

- Phils clinch playoff spot despite loss

- Reds trim magic number to 1, rout Padres

- Mariners halt Rays' winning streak at 4

- Sloppy Braves fall to Nationals 4-2

- Yanks end skid, rally past Red Sox in 10

- Lee to start playoff opener for Rangers

Bearing Temperature

Condition monitoring has proven important in the installation and maintenance of all types of turbomachinery. Bearing temperature is primarily important because bearings are the critical links between the rotating and stationary components in a machine. If temperatures are taken in the correct location, then Babbitt metal temperatures can be the best indicators of a bearing's operating condition.

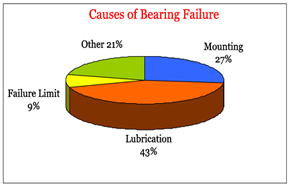

Causes Of Bearing Failure

Most bearing failures such as flaking and pitting, spalling, unusual wear patterns, rust and corrosion, creeping, skewing and others are usually attributed to a relatively small group of causes that are often interrelated and correctable. These causes include lubrication, mounting, operational stress and bearing selection and environmental influence.

Don't Let This Happen To You

A bearing failure will not only mean a compressor shutdown; it could also result in secondary or peripheral damage to costly internal parts. Early detection of a bearing failure may only result in an outage lasting a few days, but an undetected failure, causing major internal damage, can force an outage for weeks or months.

Thrust Bearings

Thrust bearings offerings include fixed profile designs for lightly-loaded applications and advanced tilting pad solutions for more demanding, high-load, high-speed applications. Combination thrust/journal designs are also available for applications with limited axial space.

Tilting pad thrust bearings are specially engineered for reduced power loss, oil flow and pad temperatures...for the most reliable and efficient machine performance.

Thrust Bearings

Thrust bearings offerings include fixed profile designs for lightly-loaded applications and advanced tilting pad solutions for more demanding, high-load, high-speed applications. Combination thrust/journal designs are also available for applications with limited axial space.

Tilting pad thrust bearings are specially engineered for reduced power loss, oil flow and pad temperatures...for the most reliable and efficient machine performance.

Ut wisi enim ad minim veniam, quis nostrud exerci tation

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

Ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismodnt ut laoreet dolore magna aliquam era

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

Sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquamnt ut laoreet dolore magna aliquam

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

Diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

Dolor sit amet, consectetuer adipiscing elit, sed diam nonummy

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummydolor sit amet, consectetuer adipiscing elit, sed diam nonummydolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.