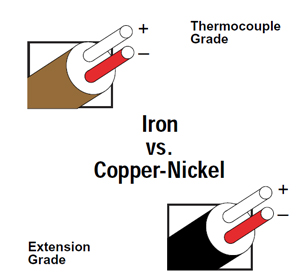

TYPE J THERMOCOUPLE (Iron/Constantan)

Composed of a positive leg which is iron and a negative leg which is approximately 45 % nickel-55% copper. (Note - Constantan is Copper-Nickel.)

When protected by compacted mineral insulation and appropriate outer sheath, Type J is useable from 0 to 816°C, (32 to 1500°F). It is not susceptible to aging in the 371 to 538°C, (700 to 1000°F) temperature range. A drift rate of 1 to 2°C, (2 to 4°F) occurs with Type E and K in the 371 to 538°C, (700 to 1000°F) temperature range. This low cost, stable calibration is primarily used with 96% pure MgO insulation and a stainless steel sheath.

Thermocouple Grade- 32°F to 1382°F, 0 to 750°C

Extension Grade- 32°F to 392°F, 0 to 200°C

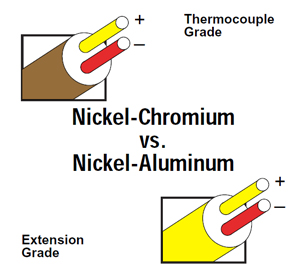

TYPE K THERMOCOUPLE (Chromel / Alumel)

Composed of a positive leg, which is approximately 90% nickel, 10 chromium and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon.

Due to its reliability and accuracy, Type K is used extensively at temperatures up to 1260°C (2300°F). It's good practice to protect this type of thermocouple with a suitable metal or ceramic protecting tube, especially in reducing atmospheres. In oxidizing atmospheres, such as electric furnaces, tube protection is not always necessary when other conditions are suitable; however, it is recommended for cleanliness and general mechanical protection. Type K will generally outlast Type J because the JP (iron) wire rapidly oxidizes, especially at higher temperatures.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

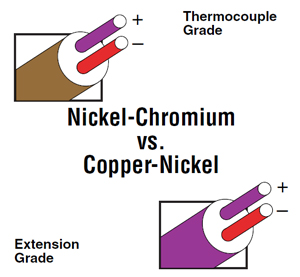

TYPE E THERMOCOUPLE (Chromel / Constantan)

Composed of a positive leg, which is approximately 90% nickel, 10 chromium and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon.

When protected by compacted mineral insulation and appropriate outer sheath, Type E is usable from 0 to 900°C, (32 to 1652°F). This Thermocouple has the highest EMF output per degree of all recognized thermocouples. If the temperature is between 316 to 593°C, (600 to 1100°F), we recommend using type J or N because of aging which can cause drift of 1 to 2°C, (2 to 4°F) in a few hours time. For applications below 0°C, (32°F), special selection of alloys are usually required.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

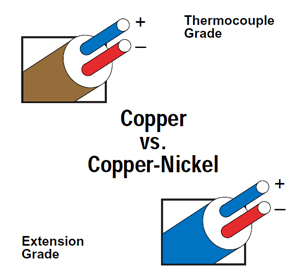

TYPE T THERMOCOUPLE (Copper / Constantan)

Composed of a positive leg, which is approximately 90% nickel, 10 chromium and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon.

When protected by compacted mineral insulation and appropriate outer sheath, Type T is usable from 0 to 350°C, (32 to 662°F). Type T is very stable and is used in a wide variety of cryogenic and low temperature applications. For applications below 0°C, (32°F) special selection of alloys are usually required.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

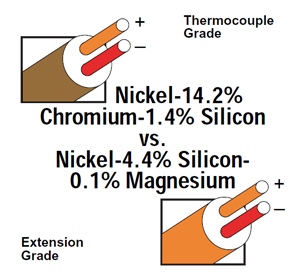

TYPE N THERMOCOUPLE (Nicrosil / Nisil)

Composed of a positive leg which is approximately 70% Platinum, 30% Rhodium and a negative leg which is approximately 94% Platinum, 6% Rhodium.

When protected by compacted mineral insulation and appropriate outer sheath, Type N is useable from 0 to 1260°C, (32 to 2300°F). Type N was developed to overcome several problems inherent in Type K thermocouples. Aging in the 316 to 593°C, (600 to 1100°F) temperatures is considerably less. Type N has also been found to be more stable than Type K in nuclear environments.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

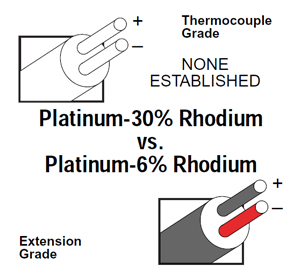

TYPE B THERMOCOUPLE (Platinum / Rhodium)

Composed of a positive leg which is approximately 14% chromium, 1.4% Silicon and 84.6% Nickel, a negative leg which is approximately 4.4% Silicon, 95.6% Nickel.

When protected by compacted mineral insulation and appropriate outer sheath, Type B is usable from 871 to 1704°C, (1600 to 3100°F). Also easily contaminated, and damaged by reducing atmospheres. The same protective measures as shown above apply to type B Thermocouples.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

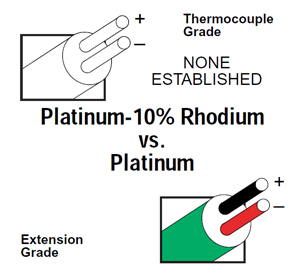

TYPE S THERMOCOUPLE (Platinum / Rhodium)

Composed of a positive leg which is approximately 70% Platinum, 30% Rhodium and a negative leg which is approximately 94% Platinum, 6% Rhodium.

When protected by compacted mineral insulation and appropriate outer sheath, Type S is usable from 0 to 1482°C, (32 to 2700°F). Easily contaminated. Reducing atmospheres are particularly damaging. Type S should be protected with gas tight ceramic tubes, a secondary tube of porcelain and silicon carbide or metal outer tubes, as conditions require.

Ut wisi enim ad minim veniam

Lorem ipsum dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna dolor ed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit m veniam volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis.

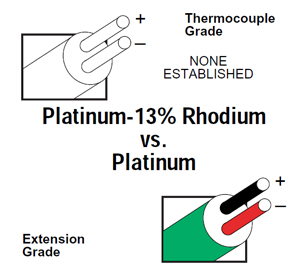

TYPE R THERMOCOUPLE (Platinum / Rhodium)

Composed of a positive leg which is approximately 70% Platinum, 30% Rhodium and a negative leg which is approximately 94% Platinum, 6% Rhodium.

When protected by compacted mineral insulation and appropriate outer sheath, Type R is usable from 0 to 1482°C, ( 32 to 2700°F).Type R has a higher EMF output than type S. Also easily contaminated, and damaged by reducing atmospheres. Type R should by protected in a similar fashion as Type S.

Thermocouple Order Code

Sheath Material

304 = 304 S.S. Most commonly used low temperature sheath material. Good corrosion resistance. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

316 = 316 S.S. Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

310 = 310 S.S. Mechanical and corrosion resistance similar to but better than 304 S.S. Very good heat resistance. This alloy contains 25% Cr, 20% Ni. Not as ductile as 304 S.S.

INC = Inconel 600 Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

Sheath Diameters

0.010"

0.020"

0.032"

0.040"

0.063"

0.313"

0.125"

0.375"

0.188"

0.500"

0.250"

Recommended upper temperature limits for sheath type thermocouples

| Type |

0.040" |

0.063" |

0.125" |

0.188" |

0.250" |

0.375" |

| J |

900 °F |

1000 °F |

1000 °F |

1200 °F |

1200 °F |

1200 °F |

| K |

1400 °F |

1800 °F |

1800 °F |

2000 °F |

2000 °F |

2000 °F |

| T |

300 °F |

400 °F |

400 °F |

700 °F |

700 °F |

700 °F |

| E |

800 °F |

1000 °F |

1000 °F |

1000 °F |

1100 °F |

1200 °F |

NOTE: The recommended temperatures shown are suggested maximum temperatures at which a thermocouple should yield satisfactory life. Due to the variables of each application, in certain instances the upper limit shown maybe exceeded without decreasing thermocouple life. Conversely, other applications may decrease service life if used at recommended upper limits. Consult our factory for suggested maximum temperatures for your requirements.

Thermocouple Grade Wire

Calibration

Type |

Temperature Range |

Tolerance Whichever is GREATER |

| J |

32 to 1382°F |

0 to 750°C |

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

| K |

32 to 2282°F |

0 to 1250°C |

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

| E |

32 to 1652°F |

0 to 900°C |

? 1.7°C or ? 0.5% |

? 1.0°C or ? o.4% |

| T |

32 to 662°F |

0 to 350°C |

? 1.0°C or ? 0.75% |

? 0.5°C or ? 0.4% |

| R or S |

32 to 2642°F |

0 to 1450°C |

? 1.5° or ? 0.25% |

? 0.6°C or ? 0.4% |

| B |

1598 to 3092°F

|

870 to 1700°C |

? 0.5% |

|

| N |

32 to 2282°F |

0 to 1250°C

|

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

Thermocouple Extension Grade Wire

Calibration

Type |

Temperature Range |

Tolerance Whichever is GREATER |

| JX |

32 to 392°F |

0 to 200°C |

? 2.2°C |

? 1.1°C |

| KX |

32 to 392°F |

0 to 200°C |

? 2.2°C |

? 1.1°C |

| EX |

32 to 392°F |

0 to 200°C |

? 1.7°C |

? 1.0°C |

| TX |

32 to 212°F |

0 to 200°C |

? 1.0°C |

? 0.5°C |

| NX |

32 to 392°F |

0 to 200°C |

? 2.2° |

? 1.1°C |

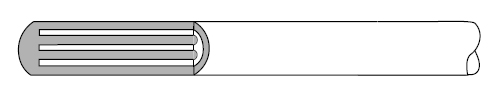

Junctions

G=Grounded

Has the fastest response time ideal for measuring rapid temperature changes. Clear coating on most models provides a humidity barrier for the thermocouple. Do not use with corrosive fluids or atmospheres. See table at right for recommended atmosphere type for exposed-junction probes.

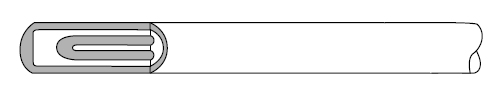

U=Ungrounded

Has a welded junction insulated from the protective sheath and is electrically isolated. Longer response time; use for conductive solutions or where isolation of the measuring circuitry is required.

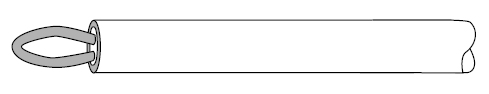

E=Exposed

Has a junction welded to tip of sheath. Wires are completely sealed from contaminants. Good response time

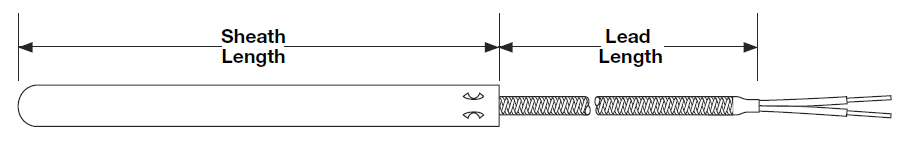

Immersion Length/ Sheath Length

Length of sheath is measure from the sensing junction to the beginning of the first fixed obstruction, termination or transition.

Leadwire

L1=Wire Exposed

L2= PVC Insulated Lead Wire (Rated 105°C, Epoxy Potted)

L3= Teflon Insulated Lead Wire (Rated 204°C, Epoxy Potted

L4= Fiberglass Insulated Lead Wire (Rated 204°C, Expoxy Potted)

L5= Fiberglass Insulated Lead Wire (Rated 510°C, Ceramic Cement Potted

CC= Coil Cord

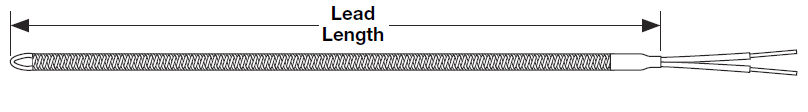

Lead Length

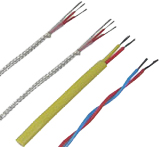

Protective Coverings

SS = Stainless Steel Overbraid

TCTU = Tinned Copper Overbraid

FA* = Stainless Steel Flex Armor

TFA* = Teflon Coated Stainless Steel Flex Armor

PFA* = PVC Coated Stainless Steel Flex Armor

* Add Length to Armor Code. (Example: PFA24)

Terminations

P = Male Plug *(MP= Mini Plug)

J = Female Jack * (MJ= Mini Jack)

ASCH = Aluminum Screw Cover Head

PH = Plastic Screw Cover Head

MPH = Mini Plastic Screw Cover Head

MAH = Mini Aluminum Screw COver Head

EXH = Explosion Proof Head (USL,CSA)

HCH = Hinged Cover Head

HPH = High Profile Hinged Screw Cover Head

SL = Spade Lugs (#10 Screw Size)

BW = Bare Wire

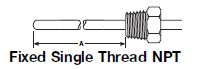

Fixed Fitting

| FXS |

|

NPT |

| 1 |

= |

1/8" |

| 2 |

= |

1/4" |

| 3 |

= |

3/8" |

| 4 |

= |

1/2" |

| 5 |

= |

3/4" |

| 6 |

= |

1" |

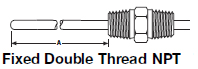

| FXD |

|

Head/Process |

|

= |

1/8" x 1/8" |

| 2 |

= |

1/4" x 1/4" |

| 3 |

= |

1/2" x 3/8" |

| 4 |

= |

1/2" x 1/2" |

| 5 |

= |

3/4" x 3/4" |

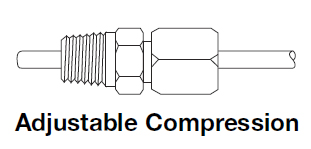

Adjustable Fittings

| N.P.T |

|

I.D. |

|

S.S |

|

BRASS |

|

C.S. |

| 1/8" |

= |

1/16" |

= |

SSF2 |

= |

BF2 |

= |

SF2 |

| 1/8" |

= |

1/8" |

= |

SSF4 |

= |

BF4 |

= |

SF4 |

| 1/8" |

= |

3/16" |

= |

SSF7 |

= |

BF7 |

= |

SF7 |

| 1/4" |

= |

3/16" |

= |

SSF8 |

= |

BF8 |

= |

SF8 |

| 1/8" |

= |

1/4" |

= |

SSF9 |

= |

BF9 |

= |

SF9 |

| 1/4" |

= |

1/4" |

= |

SSF10 |

= |

BF10 |

= |

SF10 |

| 1/2" |

= |

1/4" |

= |

SSF11 |

= |

BF11 |

= |

SF11 |